F.I.P.F.G. – Form In Place Foam Gasket

F.I.P.F.G. – Form In Place Foam Gasket

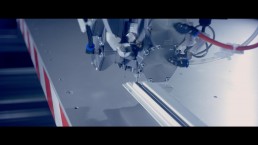

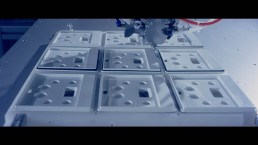

C.E.L. stands out for the constant attention paid to the increasingly high demands and expectations of our customers. And it is to satisfy this that C.E.L. enriches the production service offered through the new FIPFG sealing system (Form In Place Foam Gasket) by Sonderhoff, designed to deposit a seal of Bicomponent Expanded Polyurethane directly (In Situ) on plastic and metal parts.

With this technology C.E.L. is able to provide your products with special protection levels against the penetration of fluids, humidity and dust that are difficult to reach with traditional methods, up to an IP67 degree of protection.

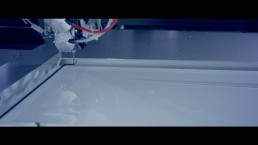

Thanks to this special sealing system it is possible to improve the hermetic properties of the products compared to the traditional punched gaskets, O-rings, rubber cords and other sealing systems. The polyurethane gasket deposited using the F.I.P.F.G. system it adheres perfectly to the plastic or metal surface on which it is dispensed, so component handling is improved and simplified in all subsequent assembly or maintenance phases.

It is possible to deposit the gasket, always ensuring perfect tightness, even on parts with geometries that are difficult to achieve with traditional methods. Thanks to the versatility of the dispensing process, it is also possible to make discontinuous sections of thickness during the path of the perimeter of the piece thanks to the possibility of varying the speed during the execution of the gasket. An efficient water tightness is often of vital importance for the finished product which must be produced with peculiar features such as elasticity and flexibility in order to adapt to irregular sealing profiles.

Other features, besides those previously mentioned, are the excellent chemical resistance to many aggressive elements, the absence of water absorption, aging resistance and UL approval.

Our proposals and applications

C.E.L. is able to offer the customer solutions with thixotropic polyurethanes, ideal for flat sealing surfaces, or solutions with self-leveling polyurethanes, useful to fill the depth of the groove homogeneously. It is for this reason that we always recommend to contact our Technical Department already during the product design, in order to be able to choose together the component geometry to achieve the best gasket deposition and thus guarantee perfect tightness. We are also equipped to provide first samples and then produce small or large batches.

This processing is offered both on the products manufactured internally and on items supplied by the Customer on a contract manufacturing base.

Application sectors

- Automotive: engine compartment, bodywork, passenger compartment, air filters;

- lighting technology: civil and road, lamps;

- electrical and electronic: cabinets and electrical panels, sensors, control units;

- household goods: boilers, air conditioners, washing machines, dishwashers, hobbyists;

- furniture: wardrobes

- mechanical components: pumps, reducers, electric motors;

- cleaning: vacuum cleaners, floor washers, cleaning trolleys, pressure washers;

- sound: speakers, speakers.

C.E.L. it is also able to supply the same type of gasket on a double-sided tape. This special gasket can be applied directly by the customer on the pieces. In the attached file you will find all the dimensions and features of this sealant. We can also supply custom-made gaskets without the adhesive tape, leaving the customer the freedom of how to apply.

Our Technical Department is at your complete disposal to show in detail the possible applications, to advise you on which product to use to satisfy your sealing needs and to design with you the best geometry of the part in order to be able to deposit the Bicomponent Polyurethane Foam gasket.